The 10-Minute Rule for Digital Printing

Table of ContentsAll about Digital PrintingOur Digital Printing StatementsAll About Digital Printing

The liquid ink sticks to the substrate with an electrostatic fee, ensuring dynamic colours and sharp information. Digital printing also requires very little setup. Although modern-day lithographic technology has minimized setup times to around 15 minutes, electronic printing still brings about comfort with its near-instant preparedness. Furthermore, electronic prints completely dry instantaneously, unlike lithographic prints, which call for 2-3 hours to completely dry. This removes smearing threats and the demand for drying out shelfs. Here are the essential methods in which digital printing supports greener practices: One of the significant environmental benefits of digital printing is lowering waste. Typical printing approaches, like lithographic printing, often waste considerable quantities of paper and ink during the configuration stage. Digital printing removes the demand for plates and various other consumables, minimizing waste throughout the manufacturing procedure. A few of the most usual applications include: Digital printing is perfect for developing business cards, flyers, posters and other advertising materials. It permits fast turnaround times and affordable production, specifically for businesses with smaller print runs. Digital printing is increasingly made use of in the product packaging sector to develop special, custom-designed product packaging.

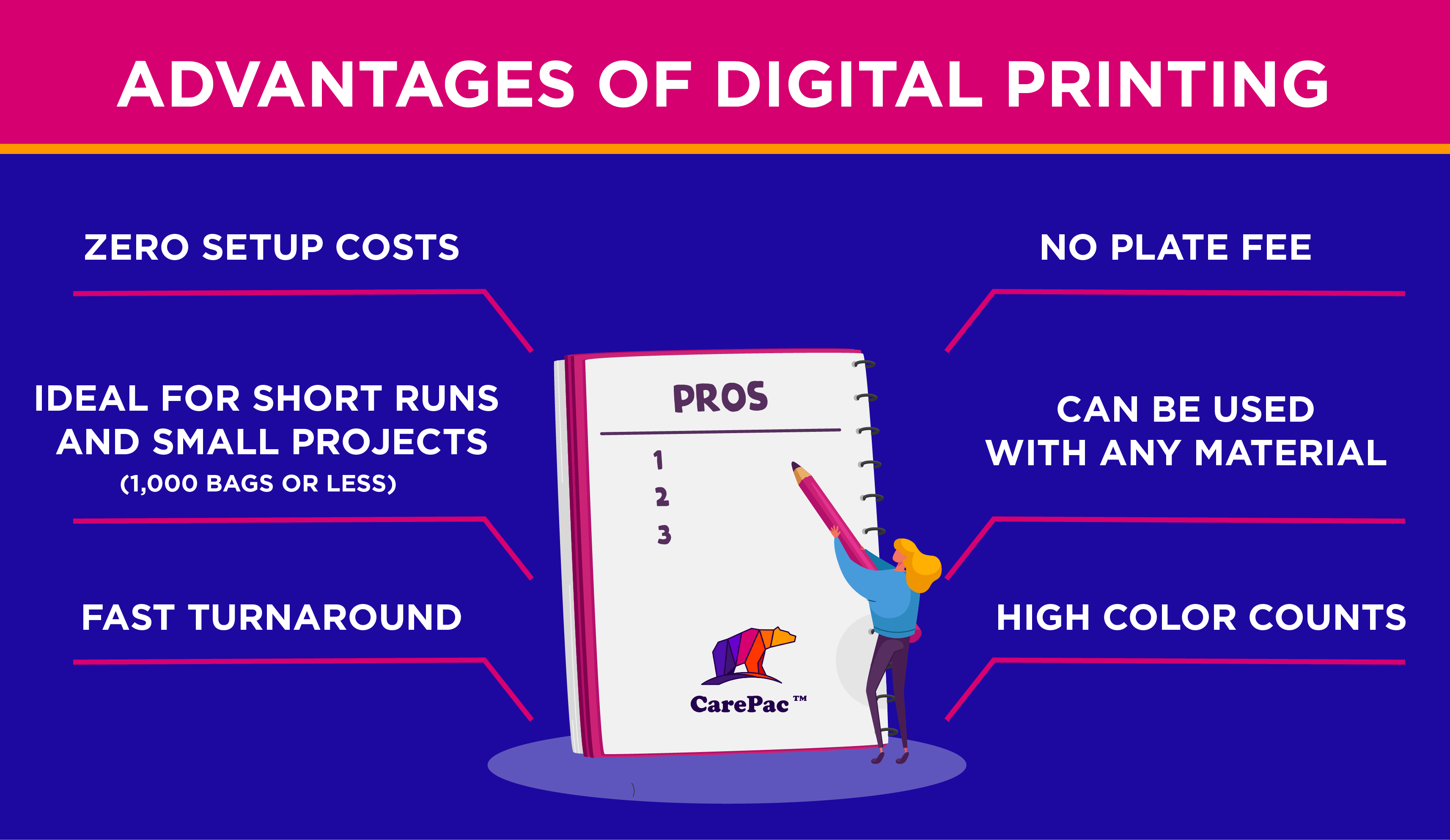

Digital printing presses eliminate the need for these plates, significantly minimizing arrangement prices. Digital printing presses can incorporate variable information into your prints, which enables extremely individualized marketing products (Digital Printing). By individualizing your marketing materials, you can increase engagement with prospective customers and enhance the chances of converting them right into real clients

In electronic printing, there are 2 various printing modern technologies to choose from: scan printing and single-pass printing. As a fairly brand-new printing modern technology, Single-pass printing can not only enhance publishing speed, however likewise increase printing quality, nonetheless, this requires more nozzles to be set up on the printing device. Company proprietors that have utilized digital inkjet printing makers understand that textile digital printing is finished generally by the printheads and printing inks.

Printers should use much more fluid inks to prevent nozzle clogging and printhead failure. In order to protect against rust of the nozzle, the ink for digital printing is a lot more pricey than the ink for traditional printing, and added ink filtration is essential during the printing procedure. On top of that, the benefit of digital inkjet printing is obvious only when utilizing inks with a large shade gamut. The digital inkjet printing press nearly understands the automatic control procedure. In digital inkjet printing, the pattern is directly published on the textile, getting rid of the plate making in rotary screen printing. It not only saves the beneficial time of plate production, yet likewise conserves the extra expense of plate production. At the exact same time, increasingly more brand names are currently increasingly more accepting of paying higher prices for faster distribution, such as delivering a set of materials within a week and even 3 days, rather than weeks and months - Digital Printing. Yes, are a lot more pricey than typical printing inks, however the digital printing procedure can save ink usage.

Today, the electronic direct-injection printing press has gone from proofing to the phase of medium-sized and large-sized manufacturing. The digital direct-injection equipment has actually gone with the promo period and went into the development and maturity period. Both printing homes and brand proprietors know the development capacity of digital printing, and agree to raise investment in digital printing. The print high quality can in some cases also competing that of countered printing. Digital printing is more economical for short print runs since it calls for much less pre-press activities and much less setup than balanced out printing. If an error in countered printing is not captured prior to the plates are made, it will certainly be extremely expensive to make new ones. While every person best regards hopes that mistakes will be avoided, it is reasonable to prepare for their potential improvement. Furthermore, its precision is extremely high. This makes certain harmony in appearance throughout the board, minimizing the likelihood that any piece will certainly require to be thrown away due to flaws. Making sure home plates are in place, the ink key is adjusted, and all the necessary adjustments have been made is a lengthy procedure when countered printing. Lowered pre-press actions mean less time is needed to set up the press. This causes a marked acceleration of turn-around time. When you need printed products promptly, this is a terrific alternative. Digital dig this printing can be a lifesaver when you obtain an order at the last minute.

has the benefit of only printing what you need. Countered printing's high configuration my review here expenses stop it from being economical for runs of 100, 10, or perhaps a single duplicate. A tailored message is constantly well gotten by clients. Digital printing permits basic personalization of advertising materials. Smaller, a lot more affordable sets let firms personalize each order. Have a sale for the go back to school. Additionally, you can customize your newsletters for repeat clients by addressing them by name. Variable information printing, such as direct mail with individualized codes and addresses, is preferably suited for electronic printing. Making adjustments to your design at the last minute is much easier with digital printing. It assists in. And this printing approach guarantees accuracy, so styles will certainly always look the exact same. Options for paper stock, finishes, and other attributes will certainly remain to grow as innovation developments. When it involves printing, Seattle Style and Publish is among one of the most trusted business around. Digital quick printing just needs four actions of style, evaluation, printing and binding to get whatever done. Conventional printing covers a huge location and calls for a large investment in innovation. The financial investment of up to tens

of countless yuan has made some tiny and moderate financiers dissuaded and helpless. The core of Digital Express is software program. other As long as the software updates can maintain up, Digital Express will certainly constantly be at the leading edge of the printing industry. And a collection of software application of a number of thousand yuan is also tiny compared to a collection of devices of several

Little Known Facts About Digital Printing.

is most likely that today's needs are various from yesterday.